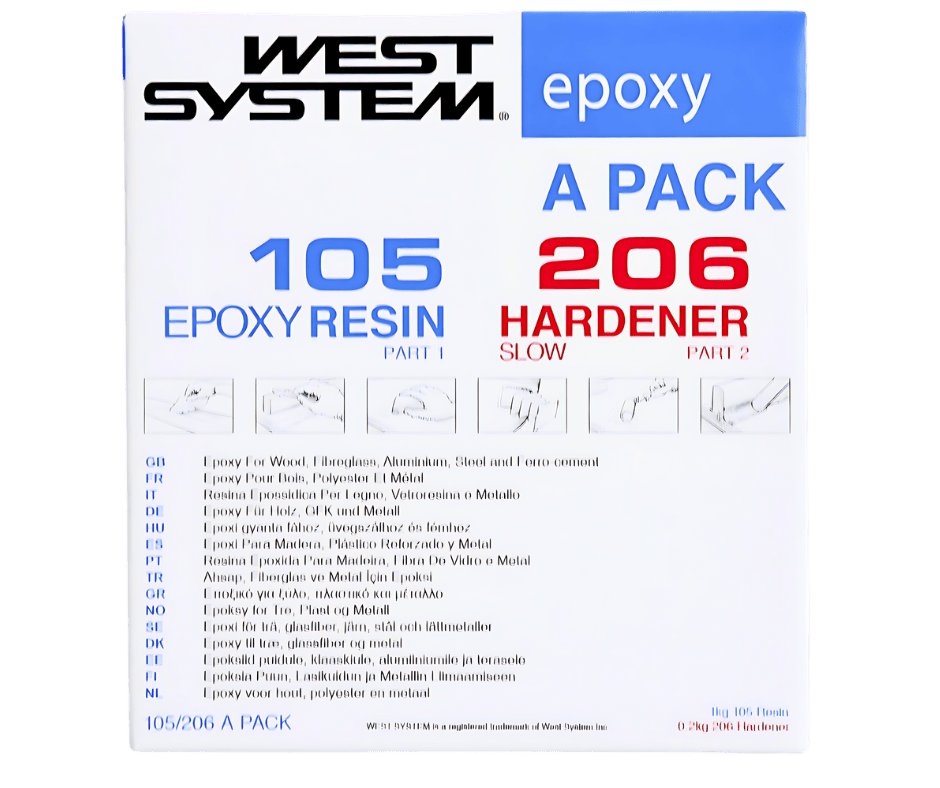

105/206 Epoxy is utilised for general coating and bonding applications where extended working and curing times are required, or to provide sufficient working time at higher temperatures.

105/206 Epoxy forms a high-strength, moisture-resistant solid with excellent bonding and barrier coating properties. It wets out and bonds to wood fibre, fibreglass, reinforcing fabrics, foam, and other composite materials, as well as a variety of metals.

105/206 Epoxy can be thickened with WEST SYSTEM® fillers to bridge gaps and fill voids. Once cured, it can be sanded and shaped. When applied with a roller, it exhibits excellent thin-film characteristics, allowing it to flow out and self-level without “fish-eyeing.” Multiple coats of 105/206 Epoxy create a superior moisture barrier and a tough, stable base for paints and varnishes. It is formulated without volatile solvents, resulting in very low VOC content. It has a relatively high flash point, no strong solvent odour, and does not shrink after curing. It is not intended for clear coating naturally finished wood.

So, what can you do with a WEST SYSTEM Epoxy A Pack?