-

Description -

Quick Links -

Resources -

Relevant Videos -

Faq -

Related Products -

Where To Buy

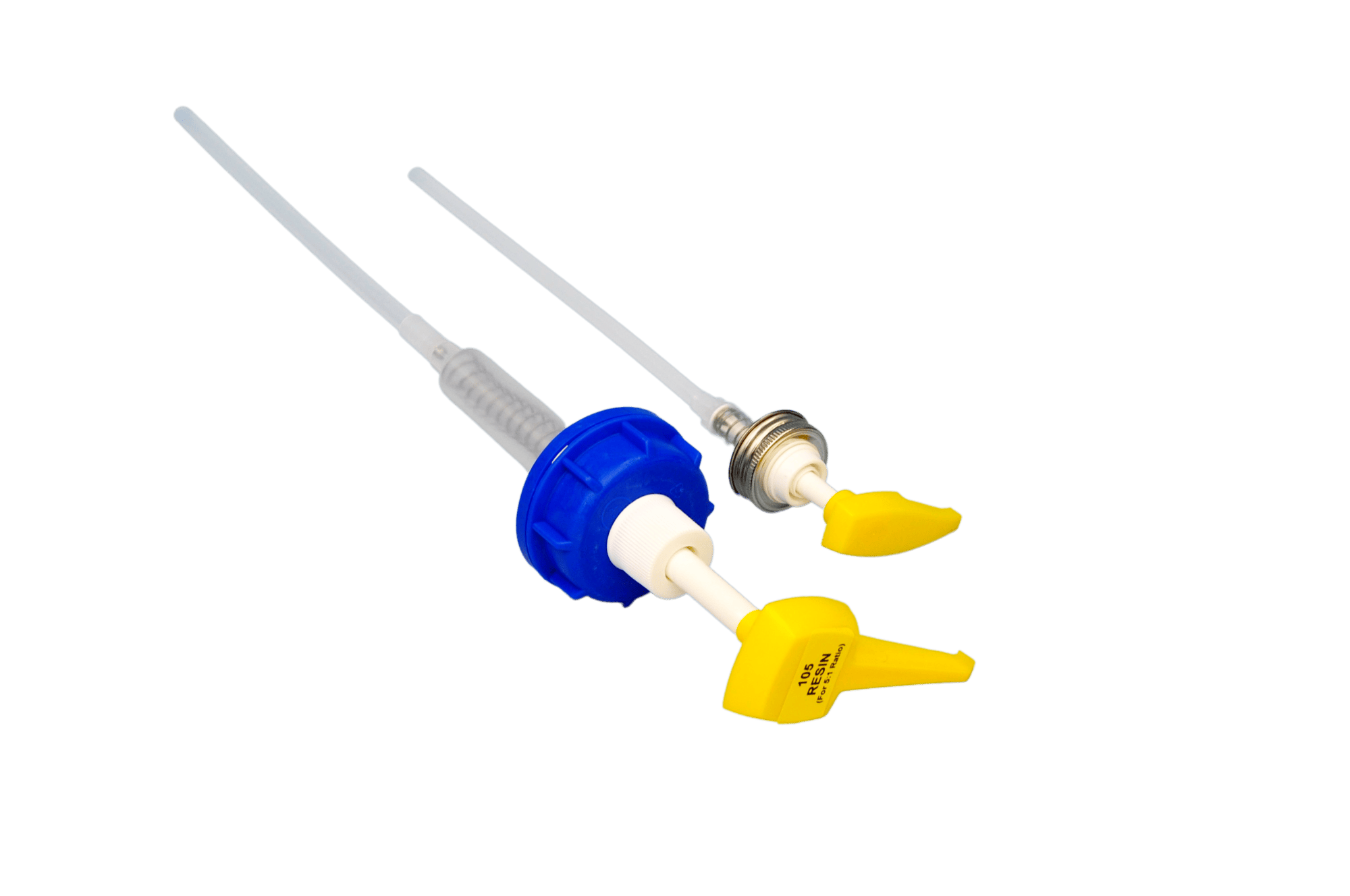

Package Includes:

- 1 Resin Pump

- 1 205/206 Hardener Pump

- Extension tubes

Product Specifications:

Calibrated to deliver the proper working ratio with one full pump stroke of resin for each one full pump stroke of hardener

Product Use:

Compatible with 105 Epoxy Resin with 205 Fast Hardener® or 206 Slow Hardener®

Getting the Most Out of Mini Pumps

QUICK LINKS Helpful Tips, Safety Guidelines, Manuals, and More:

Thickening

Modifying with fillers and additives makes WEST SYSTEM epoxy extremely versatile for a wide variety of bonding and coating applications. Epoxy can be thickened to the ideal consistency needed for a particular job. Epoxy thickened with adhesive (high-density) fillers strengthens structural bonds, bridges gaps, and fills voids. Epoxy thickened with fairing (low-density) fillers is easily sanded and shaped after it cures.