Estimating how much epoxy is required to wet out fabric is based on the fabric weight and square footage. The table below provides estimates of the amount of epoxy needed to apply 1 sq. ft. of fibreglass cloth followed by two fill coats.

| Fabric Product Number | Fabric Product Description | Weight (g/m²) | Single Layer Wet Out Thickness (mm) |

|---|---|---|---|

| 727 | 450g/m² ±45° Biaxial Glass Tape 125mm wide (Approx 13oz) as (441g/m2 = 13oz) | 450 | 0.4 |

| 729 | 175g/m² 0/90° Plain Weave Glass Tape 25mm wide (Approx 5oz) as (170g/m² = 5oz) | 175 | 0.17 |

| 730 | 175g/m² 0/90° Plain Weave Glass Tape 50mm wide (Approx 5oz) as (170g/m² = 5oz) | 175 | 0.17 |

| 731 | 175g/m² 0/90° Plain Weave Glass Tape 75mm wide (Approx 5oz) as (170g/m² = 5oz) | 175 | 0.17 |

| 732 | 175g/m² 0/90° Plain Weave Glass Tape 100mm wide (Approx 5oz) as (170g/m² = 5oz) | 175 | 0.17 |

| 733 | 175g/m² 0/90° Plain Weave Glass Tape 150mm wide (Approx 5oz) as (170g/m² = 5oz) | 175 | 0.17 |

| 736 | 332 g/m2±45o Biaxial Glass Cloth 1270mm wide (Approx = 9oz) as (305g/m² = 9oz) | 332 | 0.28 |

| 738 | 610g/m²±45° Biaxial Glass Cloth 1270mm wide (Approx = 18oz) as (600g/m² = 18oz) | 610 | 0.5 |

| 739 | 450g/m²±45° Biaxial Glass Cloth 1270mm wide (Approx = 13oz) as (441g/m² = 13oz) | 450 | 0.4 |

| 740 | 135g/m² 0/90° Plain Weave Glass Cloth 1000mm wide (Approx = 4oz) as (136g/m² = 4oz) | 135 | 0.16 |

| 741 | 200g/m² 0/90° Plain Weave Glass Cloth 1000mm wide (Approx = 6oz) as (203g/m² = 6oz) | 200 | 0.19 |

| 742 | 200g/m² 0/90° Twill Weave Glass Cloth 1200mm wide (Approx = 6oz) as (203g/m² = 6oz) | 200 | 0.19 |

| 743 | 280g/m² 0/90° 4H Satin Weave Tapered Edges 1000mm wide (Approx = 8oz) as (271g/m² = 8oz) | 280 | 0.22 |

| 746 | 260g/m² Woven Roving 1250mm wide (Approx = 8oz) as (271g/m² = 8oz) | 260 | 0.22 |

*Includes 15% waste factor. More (or less) may be needed depending on the job and personal application technique. The epoxy is applied at room temperature, approximately 72° F.

Estimating Epoxy Amounts

This formula will help you when estimating the amount of mixed epoxy needed to wet out fibreglass cloth (assuming a resin-to-fibre ratio of 50:50) and apply three rolled epoxy coats to fill the weave of the cloth, i.e. “fill coats.” The formula includes a waste factor of approximately 15%; however, more (or less) may be needed depending on the job and personal application technique. The epoxy is applied at standard room temperature, approximately 22° C.

kg of mixed epoxy=A × [(Wf + 405) * 1.15] Where: A=Total area covered by fibreglass. Units are in square metre (m²) Wf =Total weight (W) per square metre of fibreglass (f) cloth used in laminate. Units are in ounces per square yard (g/m²), i.e. 200g fibreglass cloth weighs 200g/m².

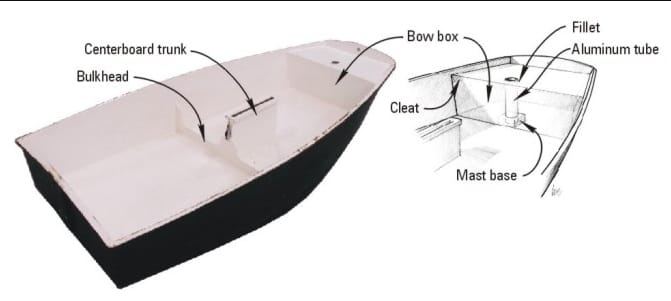

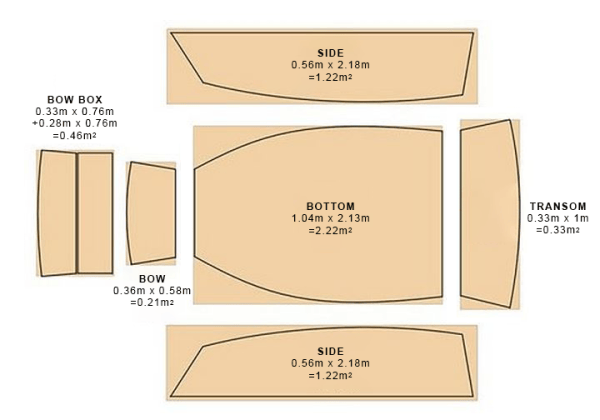

Let’s use the Optimist pram as an example:

•The outside is covered with 450g/m2 fabric and three fill coats.

Bow: 0.21m2 Transom: 0.33m 2 Side×2: 2.44m2 Bottom: 2.22m2 Total sqm: 5.2m2

•The inside is covered with 200g/m2 oz fabric and three fill coats. The bow box is covered with 200g/m2 fabric on one side only.

Bow: 0.21m2 Bow Box 0.46m2 Transom: 0.33m2 Side×2: 2.44m2 Bottom: 2.22m2

Total sqm: 5.66m2

- Outside calculation 5.20m2 x [(450g/m2 + 405) x 1.15] = 5.113kg

- Inside calculation 5.66m2 x [(200g/m2 +405) x 1.15] = 3.938kg

Total 9.051kg mixed epoxy