Vacuum bagging uses atmospheric pressure to deliver firm, even clamping pressure over the entire surface area of a composite part or repair, regardless of the material or materials being laminated. By laminating over simple moulds, composites can be moulded into an endless variety of functional shapes.

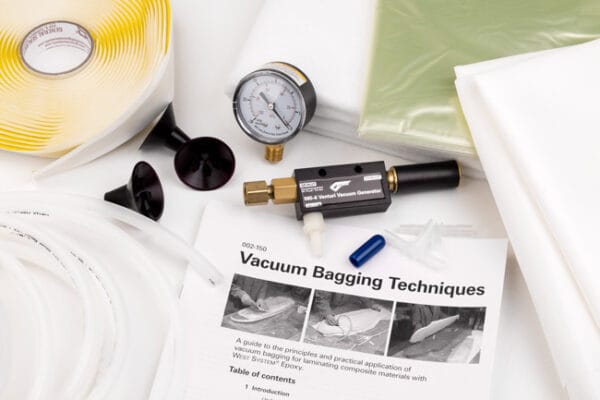

Vacuum Bagging Kit & Supplies

A complete starter vacuum bagging kit for room temperature repairs and small laminating projects up to 13 sq ft. Some item specifications may vary. WEST SYSTEM vacuum supplies can be purchased individually or as a complete kit.

It features a Venturi Vacuum Generator which delivers over 65kPa of vacuum (0.065MPa). The generator is designed to run off conventional shop air compressors to deliver at least 0.42MPa.

- Venturi Vacuum Generator with bronze muffler

- 3x Vacuum Cups (6mm in diameter)

- 3m Vacuum Tubing

- Vacuum Gauge

- 2x Junction ‘T’ Barbs

- 4m² Release Fabric

- 4m² Breather Fabric

- 4m² Vacuum Bag Film

- 5m Vacuum Bag Sealant

- Instruction booklet (002-150 Vacuum Bagging Techniques)

885-6* 1—Venturi Vacuum Generator with 885-7 Silencer.

The Vacuum Generator develops over 20 inches

Hg (mercury) of vacuum (10 psi of clamping pressure) at .4 SCFM and is designed to run off of conventional shop air compressors that continuously deliver at least 65 psi at 3.5 SCFM. Some item specifications may vary. (A ¼” NPT male air fitting is required to connect to your air compressor.)[/two_third]

Replacement Silencer

Connects to the generator to assist in limiting noise.

885-34* 3—Vacuum Cups

Cups are placed over a ½” “X” cut in the vacuum bag film and provide a port through the bag for the vacuum gauge or the vacuum tubing. 20 ft—885-4 ¼” I.D Vacuum Tubing. Cut tubing to the appropriate length, to connect the vacuum cups to the generator and make a resin trap.